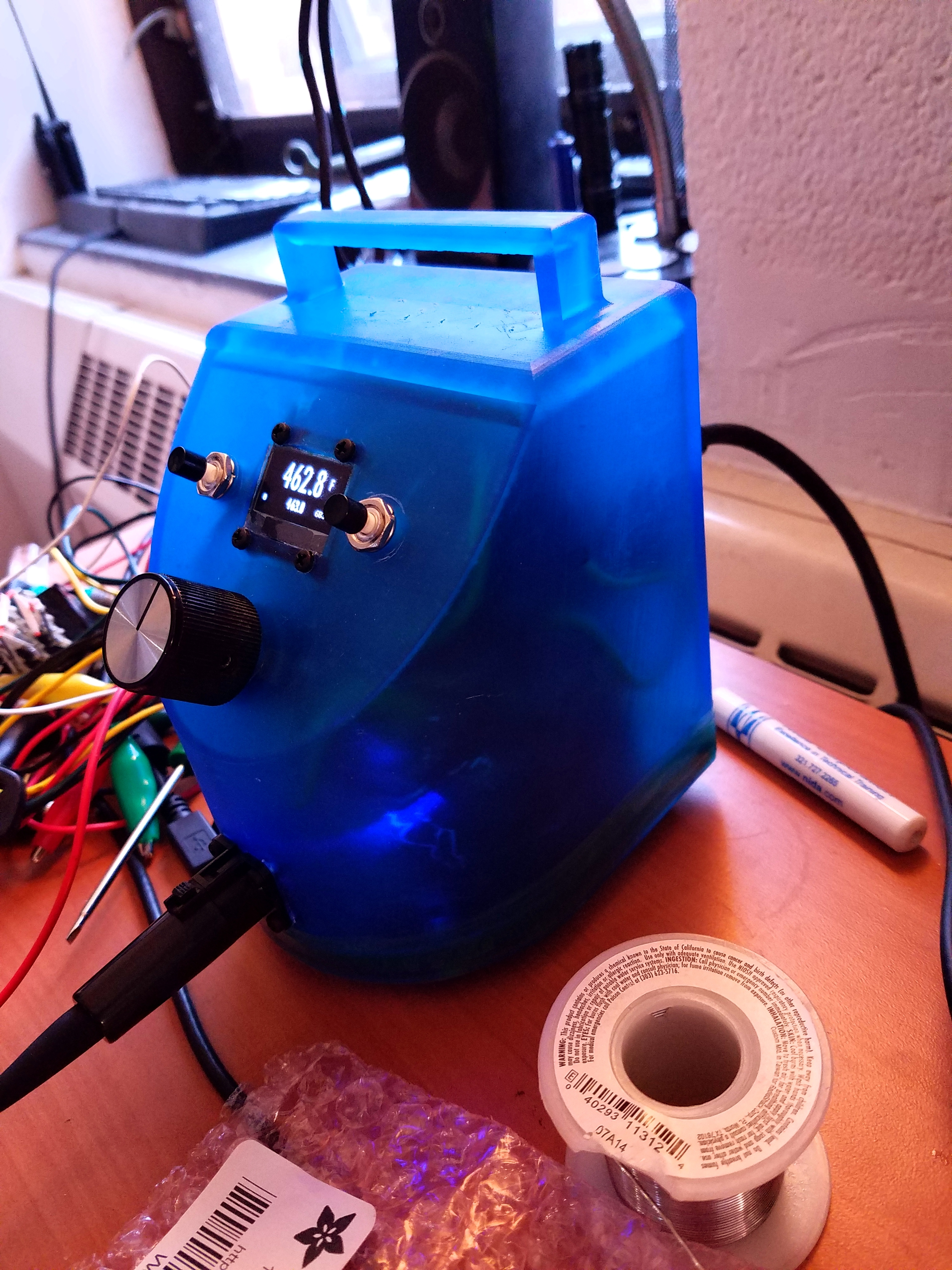

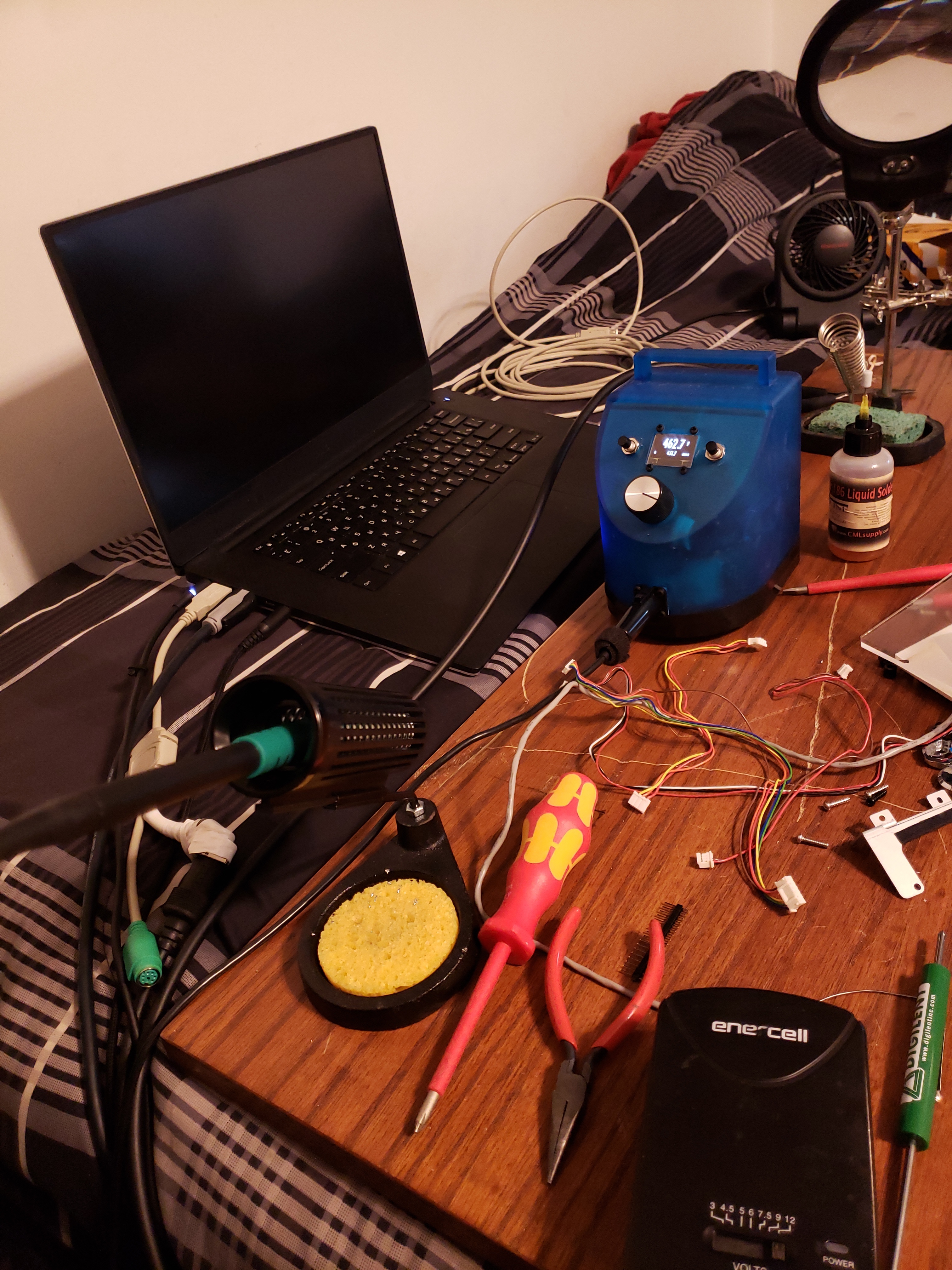

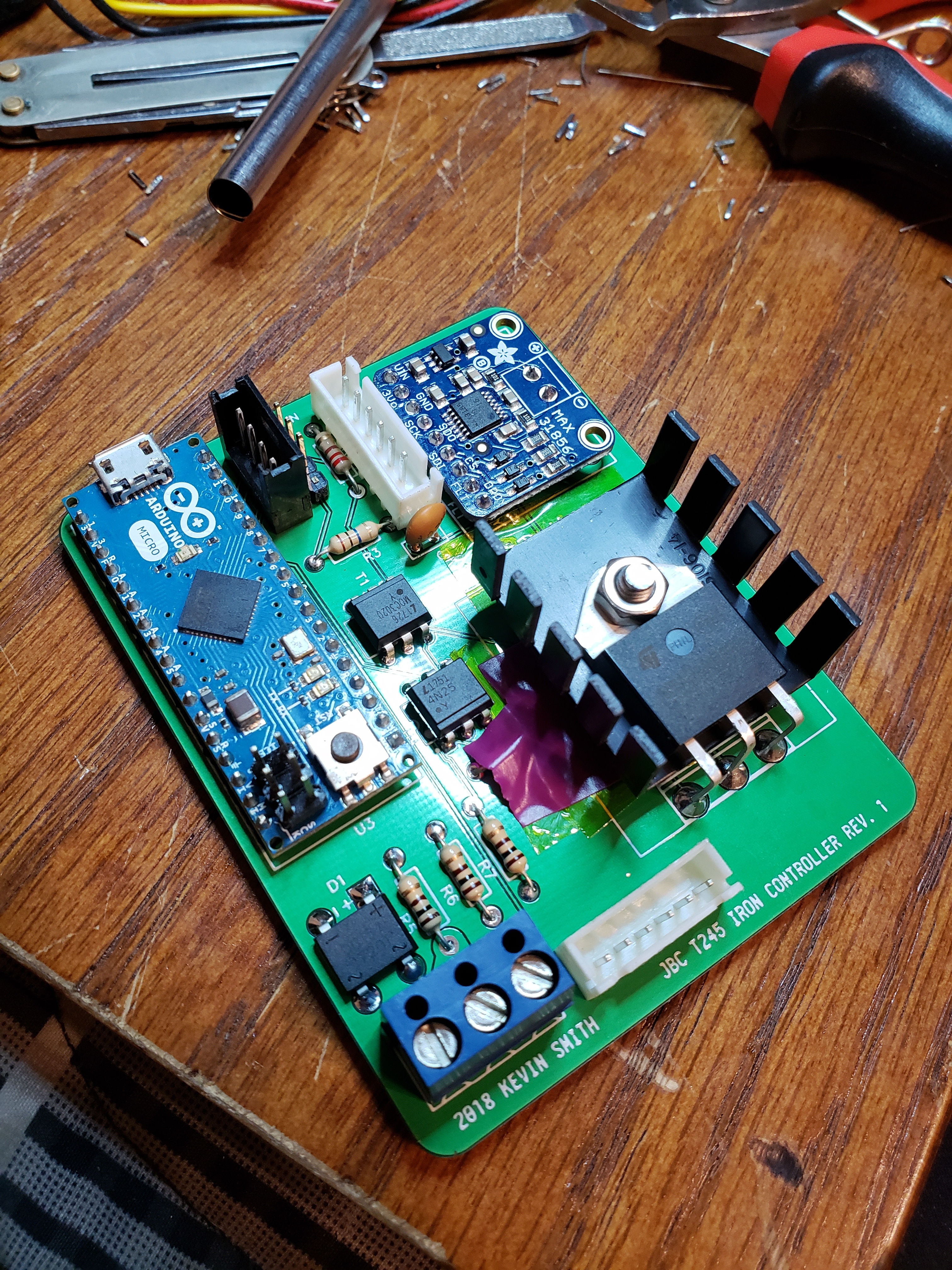

This is a project I've been working on for a little bit. Any questions are very welcome!

It's an "equivalent performance" JBC T245 soldering iron stand.

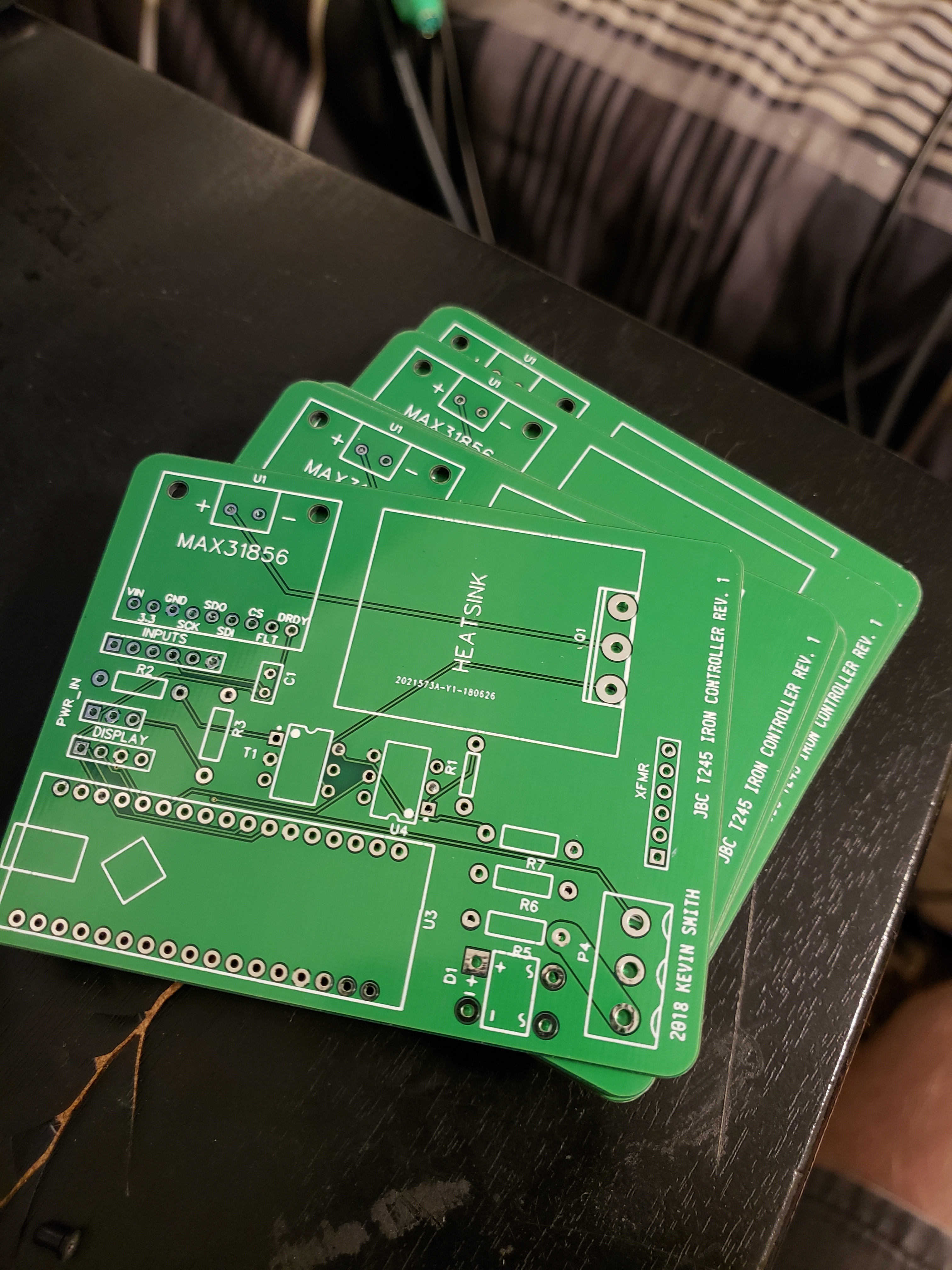

https://easyeda.com/Muny/JBC-T245-Iron-Controller

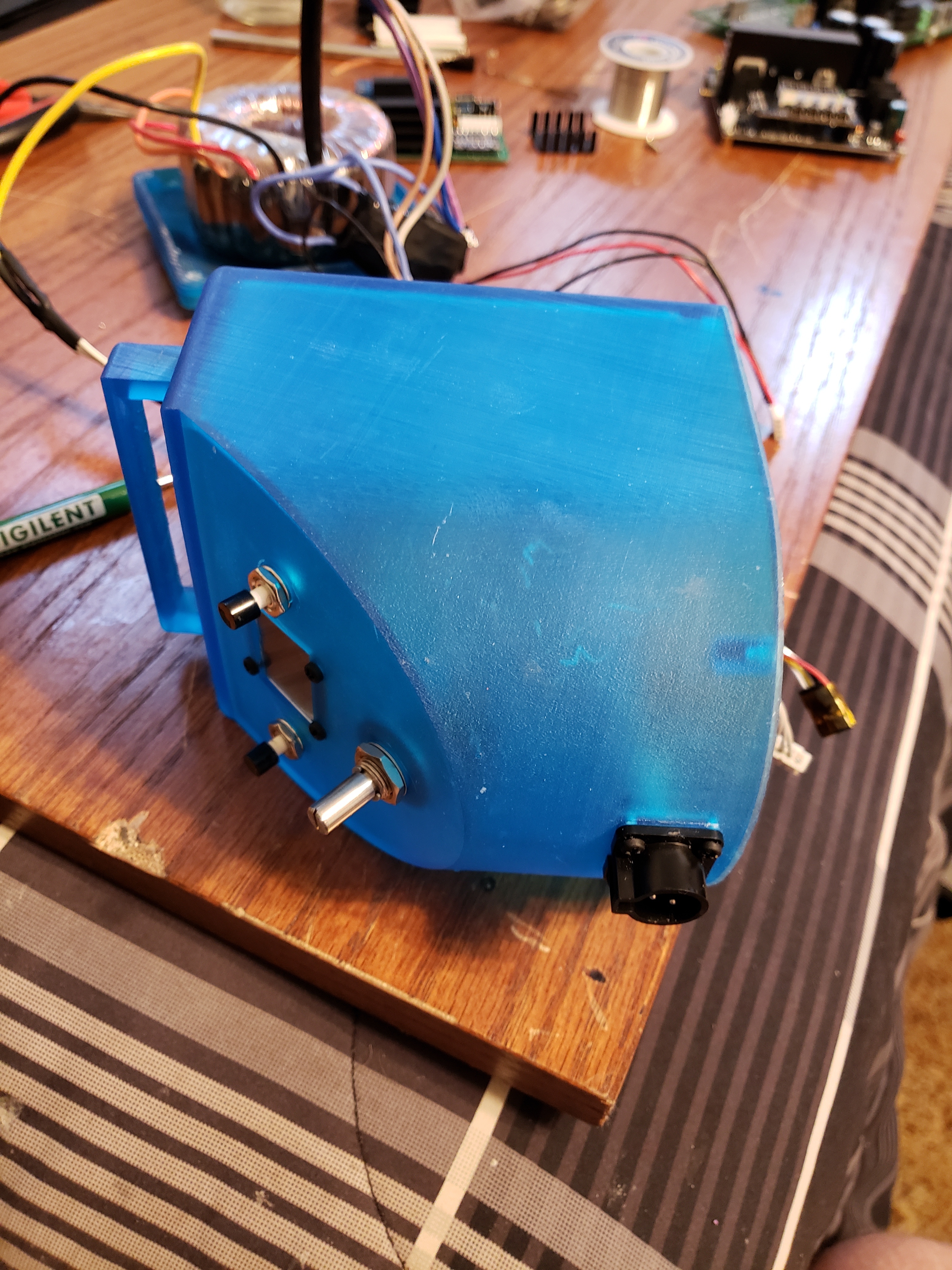

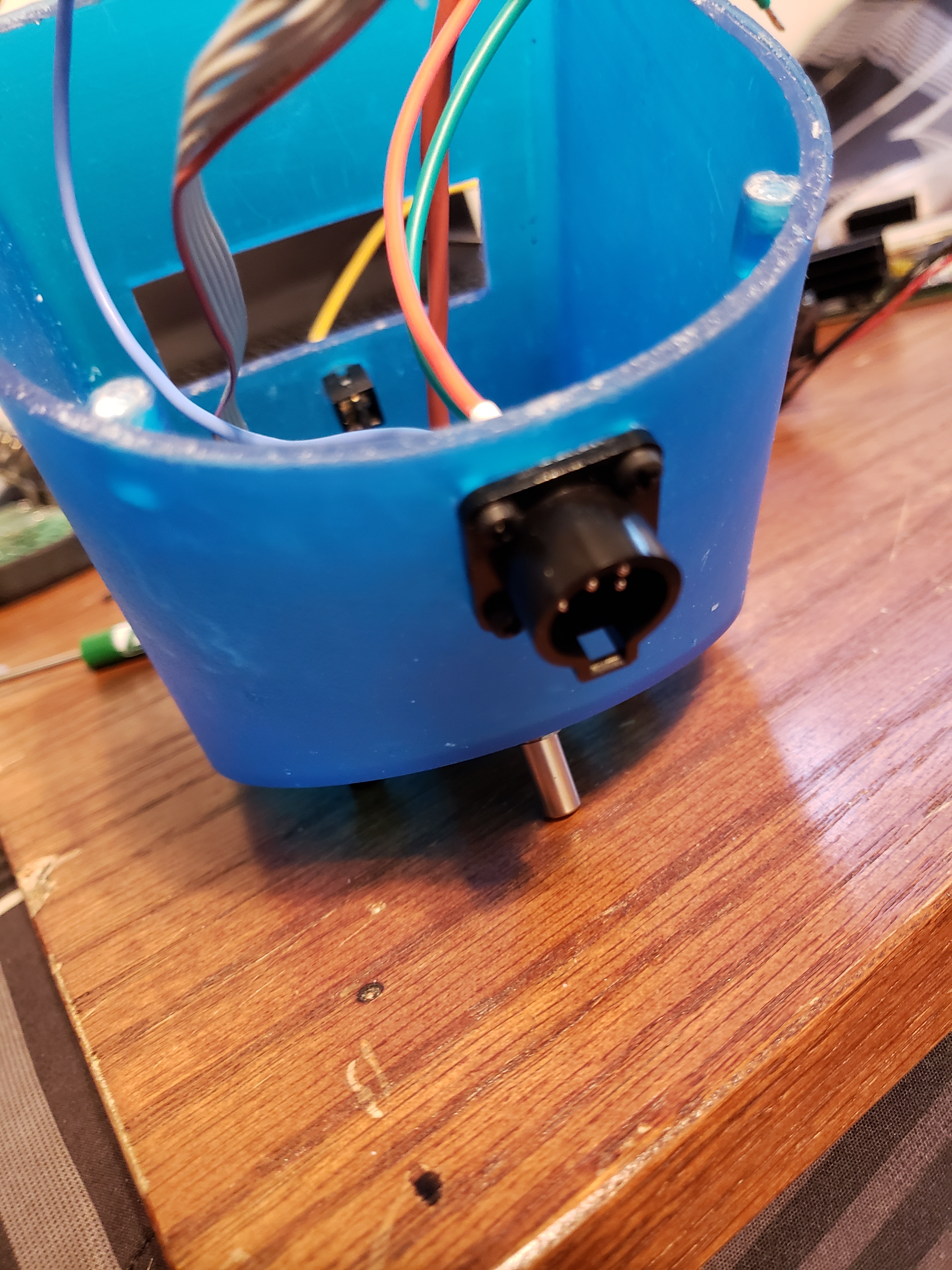

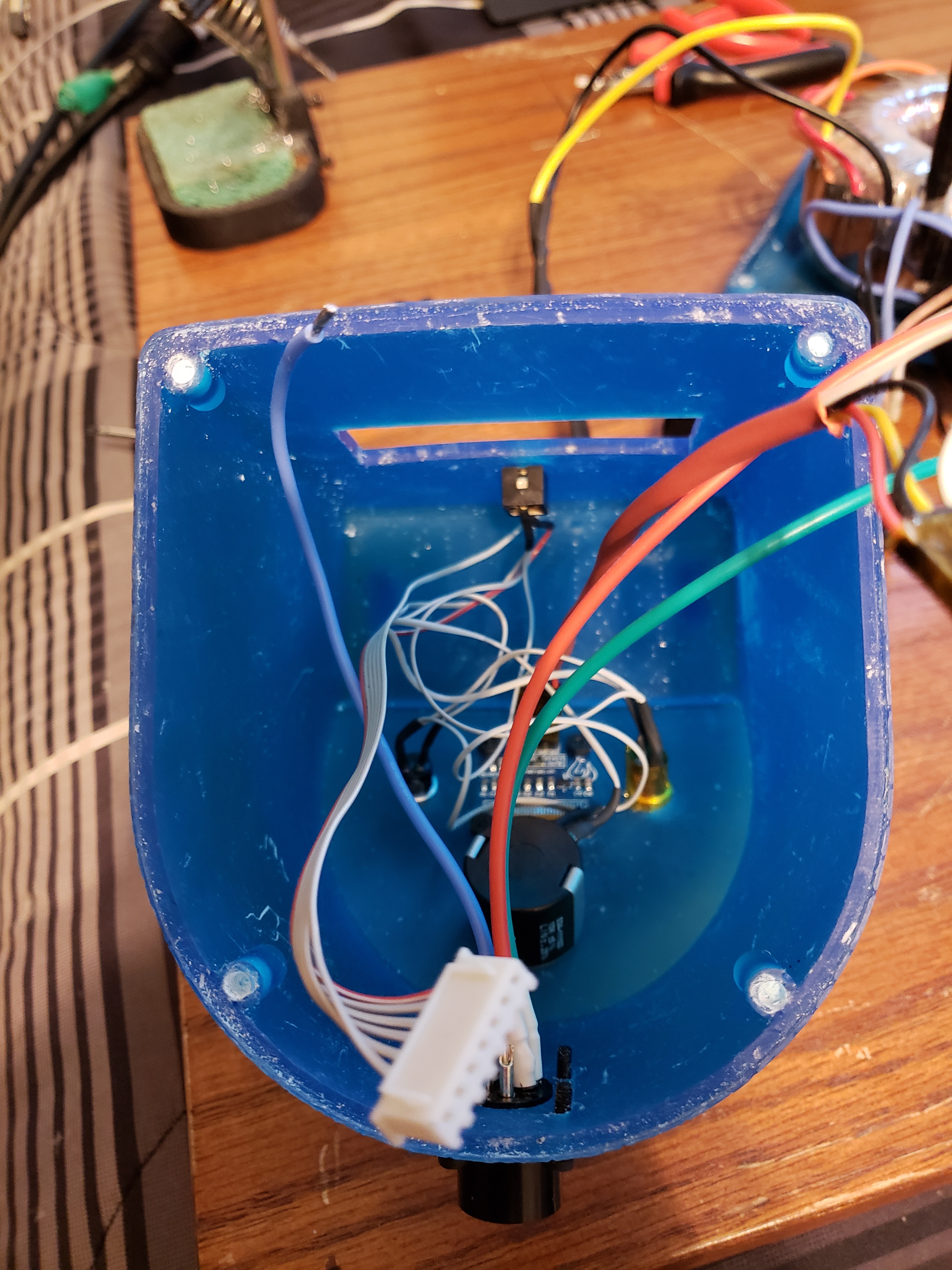

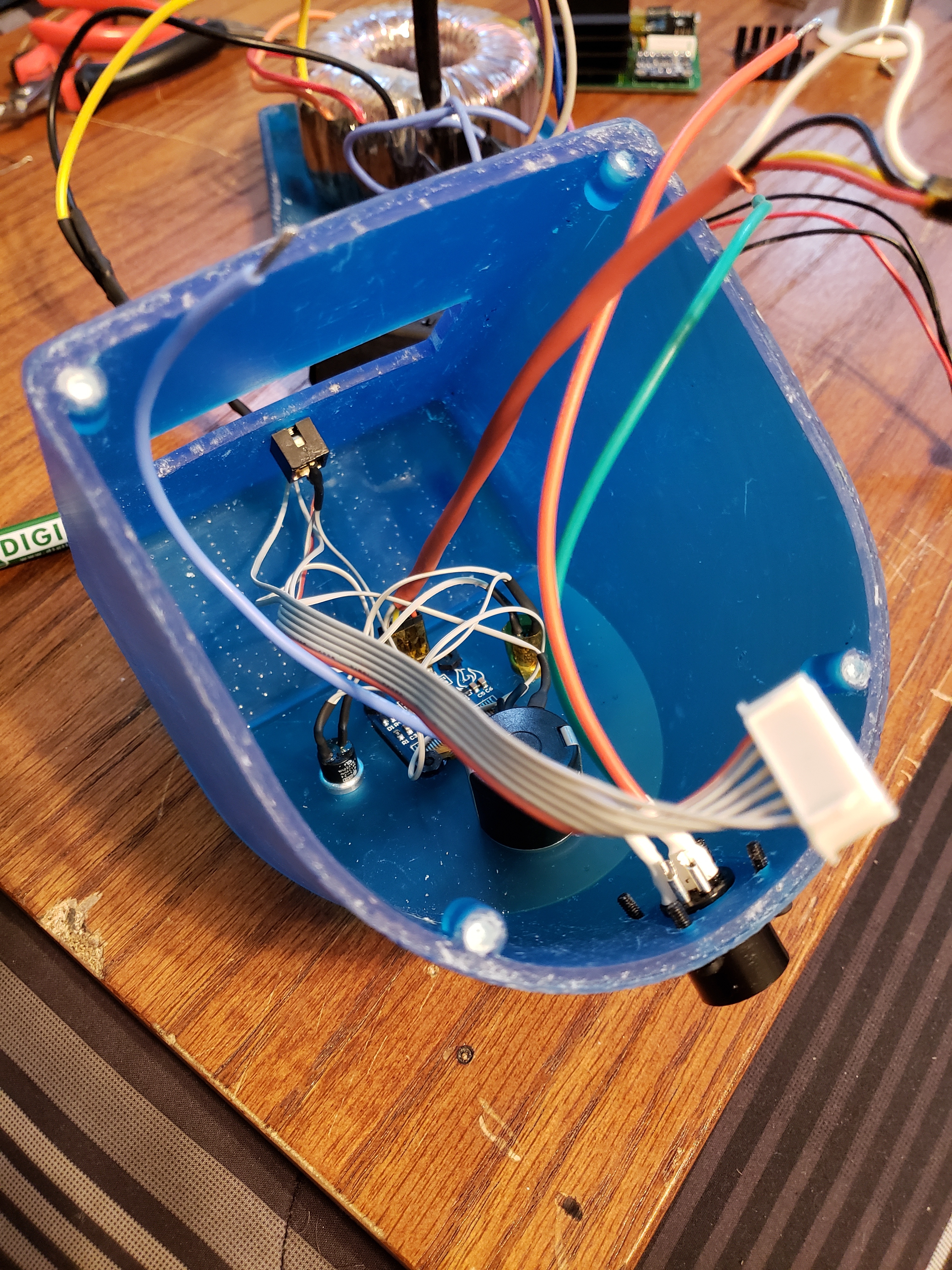

The case was designed in OpenJSCAD and printed on a FormLabs Form 2.

It uses:

- A 100VA 120v to 2x12V toroidal transformer (with the two 12v outputs in series for 24v)

- A simple isolated triac driver circuit

- A simple isolated zero crossing detector circuit

- A MAX31856 thermocouple amplifier.

- I expected the thermocouple to be of a common type, but it wasn't. So I'm only using this chip in voltage gain mode, and then plugging in the value to an equation I got by linear-fitting a couple voltage-heat data points when sticking the iron tip into liquids of varying temperature and using the melting points of leaded and lead-free solder. I'm not very worried about accuracy, but it seems to be within 10F. The output isn't linear towards the lower end though, hence the ~120F when it's actually about 80F.

- An Arduino Micro.

- The code was the most interesting part. A PID control loop was implemented using the Arduino PID library (very handy!). There is quite a bit of overshoot though, meaning I still need to tune the parameters.

It responds to heat changes extremely responsively though, as seen in the penny test at the end of the video.

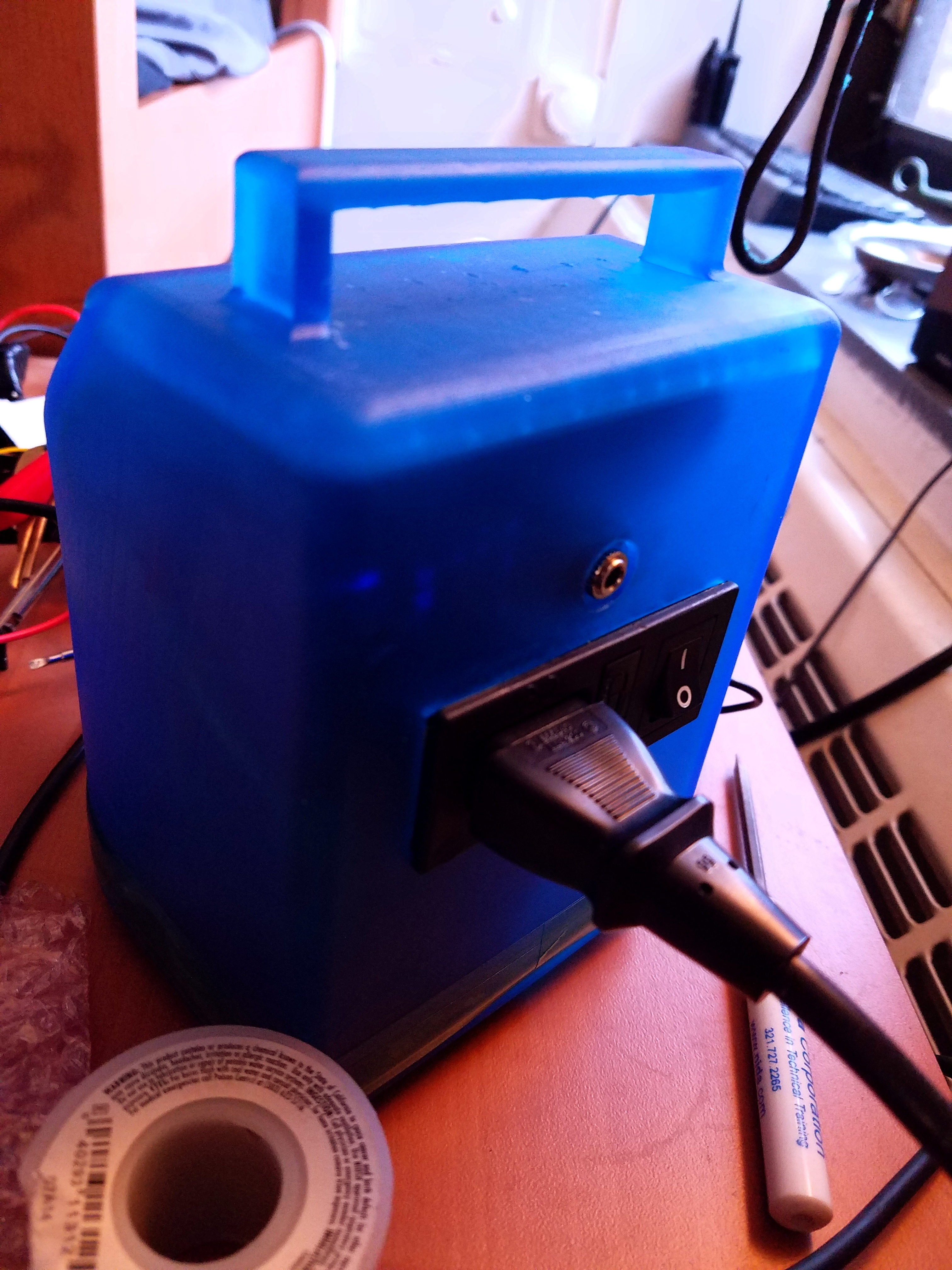

There is a jack on the back for connection to a micro-switch on a stand to put the iron into sleep mode.

Another interesting part was the final sketch size. The fonts used take up a massive portion of the available space.